The manufacturing industry is known for its traditional manufacturing processes, heavy machinery, and assembly lines. However, there has been a growing trend of hiring talent from the video game industry in recent years due to the increasing importance of Augmented Reality (AR) in manufacturing.

Traditional manufacturing processes require manual labor and high precision. However, with the increasing importance of augmented reality, the manufacturing industry is starting to see an influx of talent from the video game industry.

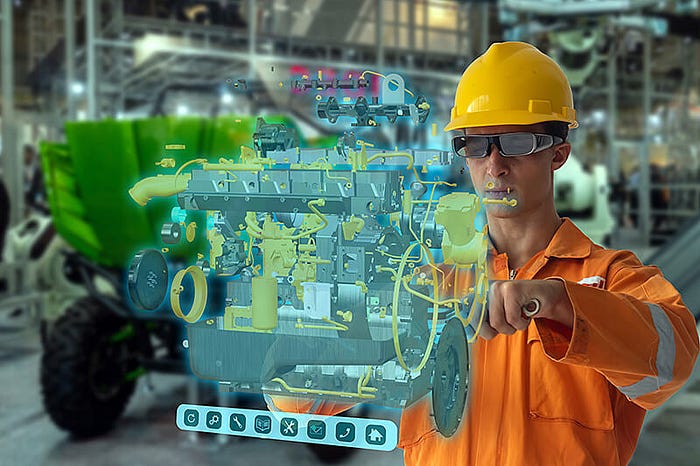

Augmented reality technology allows digital content to be overlaid in the real world. AR enhances product design, assembly, and maintenance in the manufacturing industry. It can be used to create 3D models of products, visualize how products will look in real-world environments, and provide step-by-step instructions for assembly and repair. AR can also be used to train employees on complex procedures, reducing the time and costs associated with traditional training methods.

Augmented reality is a technology that overlays digital information on top of the physical world, creating a mixed-reality environment. This technology has the potential to revolutionize the manufacturing industry by providing workers with real-time data, improving the accuracy of their work, and reducing the time it takes to complete tasks.

One of the key reasons why the video game industry is an excellent source of hire for the manufacturing industry is the skill set required to develop video games. Video game developers are skilled in creating 3D models, working with real-time graphics, and programming complex systems. These skills are highly transferable to the manufacturing industry, where they can be used to design and develop augmented reality systems.

The skills that video game industry professionals can bring to the manufacturing industry are impacting the future of manufacturing.

The video game industry has been at the forefront of Augmented Reality technology for many years. Video game developers have been creating immersive, interactive experiences for decades, and many of the skills required to make these experiences are transferrable to the manufacturing industry. One of the essential skills that video game industry professionals bring to the manufacturing industry is their ability to create realistic 3D models.

Creating highly detailed and optimized 3D models is essential for successfully implementing AR technology in manufacturing. In the manufacturing industry, 3D models are used to design products, create assembly instructions, and simulate real-world scenarios. In video games, 3D models are used to create realistic environments and characters. These models must be highly detailed and optimized for real-time rendering. This requires a deep understanding of 3D modeling software and the ability to work with complex data sets, skills highly desirable in manufacturing.

Another reason the video game industry is an excellent source of hires for manufacturing is the focus on user experience. Video game developers are experts at creating engaging and immersive experiences that keep players engaged for hours. This same focus on user experience can be applied to the manufacturing industry, where workers must be engaged and focused on their tasks for extended periods.

The ability to create engaging and intuitive interfaces is essential for the successful implementation of AR technology in manufacturing. In video games, interactivity is critical to creating engaging experiences for players. This requires a deep understanding of user experience design, interface design, and game mechanics. In the manufacturing industry, interactivity is becoming increasingly important as AR technology is used to train employees and provide real-time feedback during assembly and maintenance procedures.

Video games are often designed with a focus on user experience and engagement. Video game industry professionals also bring a unique perspective to the manufacturing industry. This perspective can be applied to the manufacturing industry to create more engaging and effective training programs, improve AR applications’ user experience, and enhance manufacturing processes’ overall efficiency.

Augmented reality systems can provide workers with hands-on training in a safe and controlled environment, reducing the risk of accidents and improving the quality of training. Video game developers are skilled at creating immersive training experiences that simulate real-world scenarios, making them a perfect fit for developing augmented reality training systems.

Augmented reality can also be used to improve the accuracy and speed of manufacturing processes. For example, workers can use augmented reality systems to overlay digital instructions onto physical objects, making it easier to follow complex assembly processes.

By hiring talent from the video game industry, the manufacturing industry can benefit from this fresh perspective and apply it to its operations, processes, and products. Augmented reality systems can also provide workers with real-time information about the status of a manufacturing process, allowing them to make adjustments and corrections on the fly.

The manufacturing industry is also starting to see an increase in the use of augmented reality in quality control. AR systems can overlay digital measurements and specifications onto physical objects, making checking for defects easier and ensuring that products meet the required standards. Video game developers are skilled at creating complex systems that can handle large amounts of data and make real-time calculations, making them an excellent fit for developing augmented reality quality control systems.

AR technology is revolutionizing how products are designed, assembled, and maintained. By using AR, manufacturers can reduce errors, improve efficiency, and enhance the overall quality of their products. The impact of this trend on the future of manufacturing could be significant.

The successful implementation of AR technology requires highly-skilled professionals with experience in 3D modeling, interface design, and user experience design that can be obtained in the video game industry. When this knowledge is merged with that of engineers and technicians in a specific sector, manufacturers gain access to the skills and techniques they need to digitize the industry.

While the video game industry is an excellent source of hire for the manufacturing industry, some challenges must be addressed. One of the key challenges is the cultural difference between the two industries. The video game industry is known for its fast-paced and innovative culture, while the manufacturing industry is often seen as slow-moving and traditional. To overcome this challenge, the manufacturing industry must embrace a culture of innovation and be open to new ideas and approaches.

Another challenge is the difference in technology between the two industries. While the video game industry is at the forefront of technology, manufacturing often uses solder systems and processes. To address this challenge, the manufacturing industry needs to invest in new technologies and be open to adopting new approaches to manufacturing.

The growing importance of augmented reality in the manufacturing industry has led to a trend of hiring talent from the video game industry, creating new opportunities for talent.

Video game professionals bring unique skills to the manufacturing industry, including creating highly detailed and optimized 3D models, creating engaging and intuitive interfaces, and providing a fresh perspective on user experience and engagement.

While some challenges need to be addressed, the benefits of hiring talent from the video game industry are clear. The manufacturing industry must embrace a culture of innovation and invest in new technologies to remain competitive, improving efficiency and reducing errors.

Leave a comment