Achieving the desired surface finish and dimensional accuracy is crucial in manufacturing and precision machining. Various techniques are used to achieve desired surface finishes, dimensional accuracy, and functional characteristics of multiple components.

Four standard methods for refining surfaces are grinding, honing, lapping, and polishing. Each of these processes possesses unique characteristics and applications. This post overviews these four methods, highlighting their fundamental principles, processes, and industrial applications.

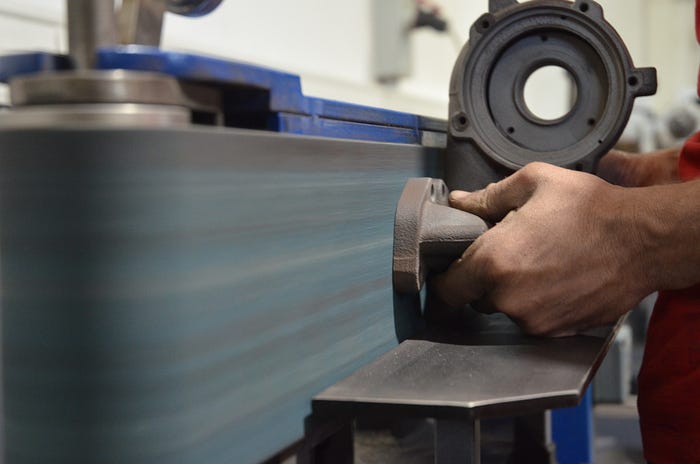

Grinding: Grinding is a widely used abrasive machining process that involves the removal of material through the use of abrasive particles. The process utilizes cutting grains bonded to the wheel’s surface, creating a fine finish and precise dimensions.

Grinding is primarily employed for removing excess material, reshaping workpieces, and improving surface roughness. Utilizes grinding wheels with abrasive grains that remove material by the cutting action of the grains.

The process involves the rotation of the grinding wheel against the workpiece, resulting in material removal through cutting and plowing actions.

Grinding can be classified into various types, including surface grinding, cylindrical grinding, and centerless grinding, depending on the shape and nature of the workpiece.

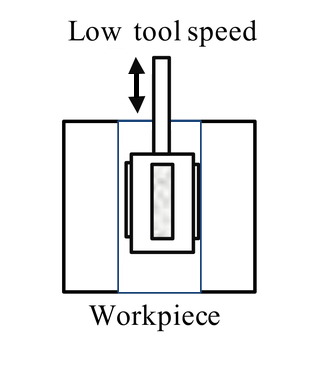

Honing: Honing is a precision machining process primarily focusing on improving cylindrical bores, holes’ geometry, and surface texture. It primarily aims to improve a workpiece’s geometric form, surface texture, and overall surface finish.

It is commonly used for internal cylindrical surfaces, such as bores and tubes.

Honing employs a set of bonded abrasive sticks, known as honing stones, that are reciprocated within the workpiece with controlled pressure. This action removes tiny amounts of material and imparts a cross-hatched pattern on the surface, leading to improved lubrication retention and reduced friction.

Honing is widely utilized in applications where tight tolerances, straightness, and roundness are critical, such as engine cylinders, stators’ internal diameter, hydraulic components, and gear manufacturing.

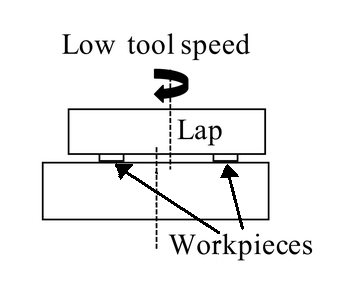

Lapping: Lapping is a process that utilizes a loose abrasive in a suspension or paste form to achieve a high degree of flatness, surface finish, and dimensional accuracy. It is often employed to finish flat or spherical surfaces, such as optical lenses, semiconductor wafers, and precision gauges.

In lapping, the workpiece is placed between two flat surfaces, known as lap plates, which are coated with an abrasive slurry. The lap plates are then rubbed together with a reciprocating or rotational motion, resulting in tiny material removal and an exact and polished surface.

Lapping can achieve extremely tight tolerances and can be used to correct minor shape deviations. It is commonly utilized for critical components in the optics, semiconductor, and precision engineering industries, where achieving exceptional flatness and surface quality is essential.

Polishing: Polishing is a surface finishing process that enhances a workpiece’s appearance, smoothness, and reflectivity. It is often employed in applications where aesthetics are important, such as jewelry, decorative items, and optical components.

It involves using progressively finer abrasives and polishing compounds to remove surface imperfections and achieve a glossy finish.

Polishing involves using polishing pads, cloths, and a fine abrasive paste or slurry. The workpiece is subjected to a combination of rotational and reciprocating motions against the polishing medium, which helps remove surface imperfections, scratches, and roughness. Polishing can result in a mirror-like surface finish, often followed by buffing to further enhance the shine and luster.

Grinding, honing, lapping, and polishing are essential processes in precision machining and surface finishing. Each technique offers unique advantages and is employed based on the application’s requirements.

At the same time, the speed at which the abrasive material moves plays a vital role in the processes because tool speed increases material removal rates — something to be considered before picking the material removal method.

Grinding provides precise material removal while honing focuses on improving geometrical attributes.

Grinding is a more aggressive process, quickly removing more significant amounts of material but may result in a rougher surface finish. On the other hand, Honing offers higher precision, allowing for tight tolerances and improved roundness.

Lapping achieves high flatness and surface finish levels, whereas polishing enhances aesthetic appeal.

Lapping provides exceptional flatness and surface quality but is limited to small areas. Polishing focuses on aesthetic appeal and produces highly reflective surfaces.

Understanding the principles and applications of these processes enables manufacturers to select the most suitable technique to achieve the desired surface characteristics for a wide range of components.

These are essential techniques in precision machining to attain desired surface finishes, dimensional accuracy, and functional properties. Each technique possesses unique characteristics and applications.

Understanding the strengths and limitations of these techniques enables manufacturers to select the most suitable method for their specific requirements, ultimately ensuring the production of high-quality components and products.

Leave a comment