Value Stream Mapping (VSM) is a lean manufacturing technique that helps businesses visualize, analyze, and improve their processes. It is an essential tool in the aviation manufacturing industry where optimizing operations, reducing costs, and improving safety is paramount.

The aviation manufacturing industry is a complex and highly competitive field that requires efficient and effective processes to remain competitive. Value Stream Mapping (VSM) is vital in this industry as it helps organizations identify and eliminate wasteful activities, reduce lead time, and increase productivity. VSM allows organizations to analyze their current processes, identify areas of improvement, and develop strategies to optimize the production flow.

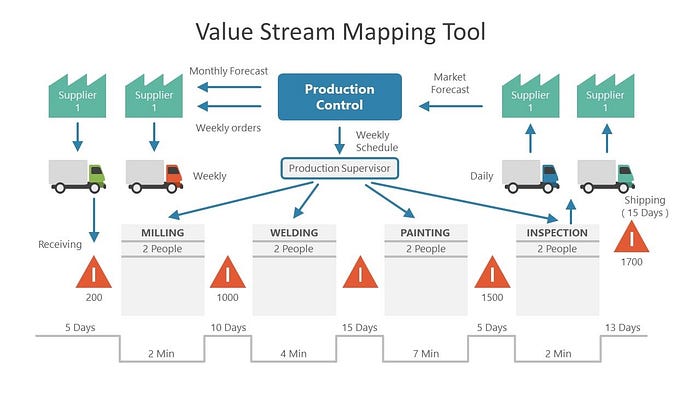

Value stream mapping provides a comprehensive overview of a manufacturing process by visually mapping every step in the production process, from raw materials to finished products. This mapping enables businesses to identify bottlenecks, inefficiencies, and areas where waste can be reduced. In the aviation manufacturing industry, where safety is paramount, value stream maps can help identify potential hazards and reduce the risk of accidents.

Get my free eBook — APQP The Ultimate Product Introduction Strategy for the Aviation Industry

Aviation manufacturing has many interdependent processes, such as design, assembly, testing, and quality control. Each process contributes to the final product, and any delay or inefficiency in one function can have a cascading effect on the entire production line.

VSM helps organizations identify these interdependencies and analyze the impact of each process on the overall production flow. This information allows organizations to optimize production flow, reduce lead time, and increase productivity.

Value stream mapping visually represents the steps in creating a product or service. Together with the work instructions and engineering drawings, it helps manufacturers identify waste, inefficiencies, and bottlenecks in their processes. Manufacturers can make informed decisions about improving their operations by understanding where value is added and where it is not.

There are many benefits to using value stream mapping in the aviation manufacturing industry. For example, value stream mapping can help manufacturers to reduce costs, improve quality, increase efficiency, speed up time to market, and improve customer satisfaction.

In addition to these benefits, value stream mapping can help manufacturers identify opportunities for innovation, improve communication and collaboration between departments, and create a more sustainable manufacturing process.

One of the significant benefits of VSM in the aviation manufacturing industry is the identification of wasteful activities. Waste is any activity that does not add value to the final product or service, such as overproduction, waiting, excess inventory, and unnecessary transportation. VSM allows organizations to identify these wasteful activities and develop strategies to eliminate them. Organizations can reduce costs, increase efficiency, and improve the quality of their final products by removing waste.

VSM can also help to identify where value is added in the manufacturing process and where it is not. By eliminating non-value-added steps, businesses can optimize their processes, reduce costs, and improve efficiency. In the aviation manufacturing industry, where every second counts, value stream maps can help save time in producing high-quality parts.

Value stream maps can also help identify opportunities for automation. By mapping out the entire process, businesses can identify areas where automation can be implemented to improve efficiency and reduce costs. Automation can also improve safety by eliminating the need for human workers to perform dangerous tasks.

Another benefit of VSM is that it helps identify where inventory can be reduced. By mapping out the entire process, businesses can identify areas where inventory can be reduced without impacting production. In the aviation manufacturing industry, where the cost of inventory can be significant, reducing inventory can help businesses reduce costs and improve cash flow.

Value stream mapping is a valuable tool for any aviation manufacturer that wants to improve its performance. By taking the time to map out their processes and identify waste, manufacturers can make significant improvements to their operations.

Here are some specific examples of how value stream mapping has been used in the aviation manufacturing industry:

- Boeing used value stream mapping to improve the efficiency of its production line for the 787 Dreamliner. By identifying and eliminating waste, Boeing reduced the production time for the 787 by 50%.

- Airbus used value stream mapping to improve the quality of its aircraft. By identifying and correcting defects in its manufacturing processes, Airbus was able to improve the reliability of its aircraft and reduce the number of customer complaints.

- Rolls-Royce used value stream mapping to improve its product development process speed. By streamlining its processes and eliminating waste, Rolls-Royce reduced the time needed to develop new products from 5 to 2 years.

These are just a few examples of how value stream mapping can be used to improve the performance of aviation manufacturers. By taking the time to map out their processes and identify waste, manufacturers can make significant improvements to their operations.

Moreover, value stream maps can help identify areas where quality can be improved. Businesses can identify potential quality issues by analyzing every step in the manufacturing process and taking corrective action. This can help reduce the risk of product recalls and improve customer satisfaction.

Value stream maps can help businesses identify opportunities for continuous improvement. By regularly reviewing and updating the value stream map, companies can identify areas for further improvements.

If you are an aviation manufacturer, consider using value stream mapping. It is a powerful tool that can help you improve your performance and achieve your goals.

Get my free eBook — APQP The Ultimate Product Introduction Strategy for the Aviation Industry

Leave a comment