Our parents teach us the basics about the world when we are kids. Most things we learn from them come from imitation or because they tell us. While we continue growing, self-identification starts gaining supremacy, and the knowledge we receive comes from our core resonance with other people’s acts and beliefs.

As no one is born knowing, every piece of knowledge we currently have, and all the ones we will have someday, comes from an external source or through experience. The way this knowledge gets fixed in us can be conscious or unconscious.

Going to school is conscious while following your favorite celebrity is an unconscious way of accumulating knowledge.

In the industry, we come with technical knowledge representing our value as employees. Once inside the company, we are trained for a position by others with knowledge and experience. Here, unconscious learning costs are high, so conditions are set so the knowledge is passed consciously.

In school, teachers verbally transmit their knowledge to us and use books with the wisdom that can be taught.

In the industry, experienced workers play the role of teachers and transmit their knowledge to new ones in a process called training.

The trainee is supposed to acquire new abilities based on previous knowledge to perform a job following technical instructions. When performing Advanced Product Quality Planning (APQP), technicians shall be capable of following Work Instructions to manufacture products in the correct sequence.

Work instructions ensure that work is done correctly, consistently, and safely. They provide a step-by-step guide for completing a task, and trained employees can use it. Work instructions can also help improve communication and collaboration between engineering, quality, and production.

Using Work Instructions provides benefits for the aviation industry:

- Improves quality: Work instructions can help enhance the quality of work by providing a clear and concise guide for completing tasks. This can reduce errors and defects and help ensure tasks are completed correctly.

- Increases productivity: Work instructions can help to increase productivity by providing a streamlined process for completing tasks saving time and money. It also helps to improve the efficiency of the manufacturing process.

- Reduces errors: By providing precise and concise instructions, work instructions help to reduce errors by providing a visual reference for technicians.

- Improves safety: Work Instructions can help to improve safety by providing employees with the information they need to work safely. Work Instructions are crucial to prevent injuries and accidents.

- Reduces training time: Work Instructions reduce training time by providing employees with a self-paced learning tool. This can save time and money.

- Improves compliance: Work Instructions can help to ensure compliance with regulations and standards, helping to avoid fines and penalties.

Overall, Work Instructions are essential for any organization that wants to improve its work quality, productivity, safety, and compliance.

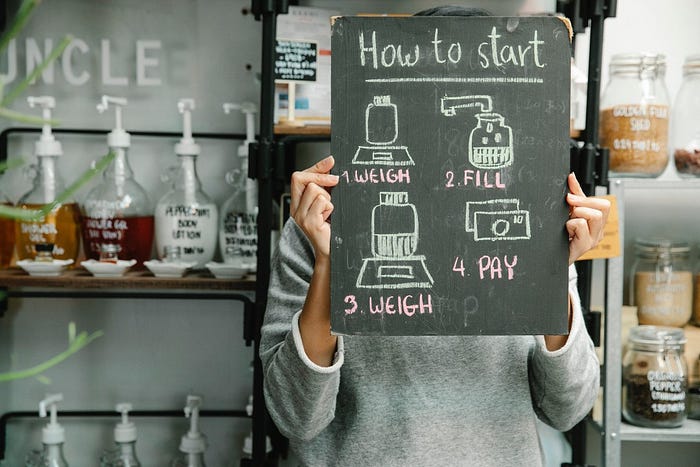

Detailed Work Instructions will provide a sequence of operations presented graphically and verbally so the message can be interpreted using different skills.

A picture is worth more than a hundred words. This is what Work Instructions are about. That is why instructions feel so intuitive in front of an IKEA piece of furniture. Those provide a list of the material and the tools to be used, a precise assembly sequence, and clarifications to avoid possible mistakes. This is what Work Instructions are about.

Here you have some tips for creating astonishing Work Instructions in the aviation Industry:

- Be clear and concise,

- Use simple language that is easy to understand,

- Use visuals, such as diagrams, schemas, and pictures, to help explain the steps,

- Number the steps in a logical order,

- Use headings and subheadings to break up the text,

- Highlight the inspection steps,

- Provide charts with the BOM and the List of Tools,

- Use a consistent format throughout the document,

- Proofread the document carefully before distributing it,

Following these tips, you can write adequate Work Instructions to help your employees complete tasks correctly and efficiently.

Overall, Work Instructions are essential to the aviation manufacturing and repair business. They improve quality, efficiency, safety, training, and regulation compliance.

If you need better-written Work Instructions, now is the time to create them. Feel free to drop me a line if you need help creating or improving Work Instructions.

Leave a comment