In the modern world, Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software have emerged as invaluable tools in various industries. CAD/CAM software combines the power of computers with design and manufacturing processes, enabling engineers, architects, and designers to create, simulate, and optimize complex products and structures.

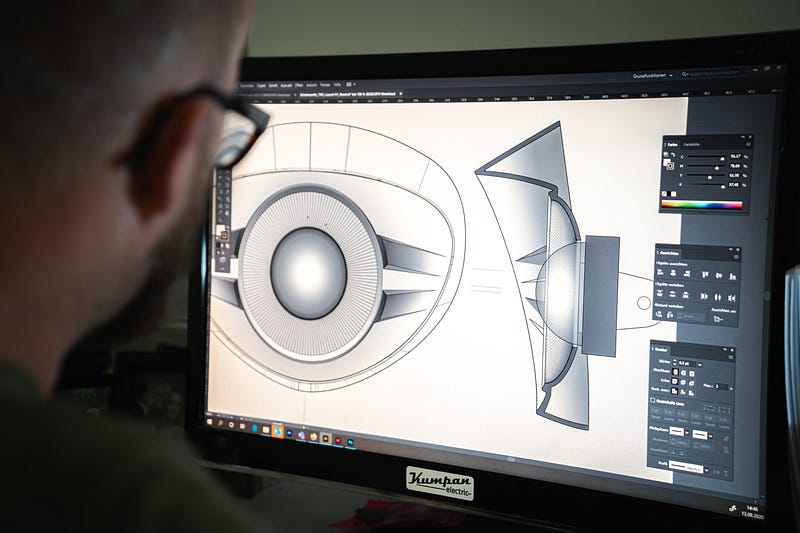

CAD software enables users to create detailed and accurate 2D and 3D models, allowing designers to visualize their ideas before production. It offers advanced tools for precise measurements, geometry manipulation, and parametric modeling, enabling iterative design and quick modifications. This enhances creativity and efficiency and reduces errors and reworks during the design phase.

CAD/CAM software facilitates seamless collaboration among multidisciplinary teams working on a project. Designers, engineers, and manufacturers can share real-time models, annotations, and specifications, ensuring everyone is on the same page. This streamlines the design-to-production process, minimizes misunderstandings, and accelerates decision-making.

This software significantly reduces design and manufacturing time by automating repetitive tasks. Design iterations can be quickly tested and refined virtually, reducing the need for physical prototypes and associated costs. Moreover, the software enables efficient material utilization and optimization, leading to cost savings in production.

Product quality is enhanced when CAD/CAM software is used. They yield detailed analyses and simulations, enabling engineers to evaluate the performance and behavior of a product before it is manufactured. Structural analysis, fluid dynamics simulations, and stress testing help identify potential flaws or weaknesses, leading to design improvements and, ultimately, higher product quality and reliability.

Integrating CAD and CAM software allows a seamless transition from design to manufacturing. CAM software interprets CAD models, generating tool paths and instructions for machine tools and manufacturing equipment. This ensures accuracy, reduces human errors, and enables efficient production planning and scheduling.

CAD/CAM software offers extensive design capabilities, allowing for intricate and complex designs previously challenging to achieve. It enables designers to explore innovative concepts, create organic shapes, and incorporate intricate details, expanding the possibilities for product development.

This type of software provides tools for optimization and analysis, enabling designers to refine their designs for better performance, efficiency, and cost-effectiveness. By simulating real-world conditions and testing different scenarios, engineers can identify design weaknesses and make informed decisions to improve product quality.

CAD/CAM software increases productivity. Automated manual tasks eliminate the need for traditional drafting techniques. This accelerates the design process, reduces errors, and increases productivity. Designers can focus more on creative and value-added tasks, leading to higher efficiency and shorter product development cycles.

Improving the documentation related to the manufacturing processes is another of the advantages of CAD/CAM software. They generate accurate and standardized documentation, including detailed drawings, parts lists, and assembly instructions. This facilitates communication between design, manufacturing, and quality assurance teams, ensuring consistent and error-free production processes.

However, not everything is pink-colored. The industry’s massification of CAD/CAM software has created some disadvantages.

Learning to use CAD/CAM software effectively requires training and experience to unleash its potential fully. Learning complex software interfaces and mastering advanced features can be time-consuming, especially for beginners. Additionally, upgrading to new software versions may require additional training, impacting productivity during the transition period.

Implementing CAD/CAM software involves significant costs, including licensing fees, hardware upgrades, and training expenses. Small businesses and individual designers may need help to afford high-end CAD/CAM software packages. Furthermore, maintaining a robust IT infrastructure and ensuring software compatibility can be demanding for organizations.

While CAD/CAM software offers numerous advantages, overreliance on these tools can limit creativity and innovation. Designers may become too dependent on pre-designed components or templates, restricting originality and hindering unique design solutions. Striking a balance between software capabilities and human creativity is crucial.

CAD/CAM software has become indispensable in today’s design and manufacturing industries. Its ability to enhance design capabilities, improve collaboration, reduce production costs, and increase productivity has revolutionized how products are conceived, developed, and manufactured. Despite some challenges, like the initial learning curve and price, the benefits offered by CAD/CAM software outweigh the drawbacks. As technology advances, CAD/CAM software will evolve, driving innovation and efficiency across various sectors.

Leave a comment