#Lean

-

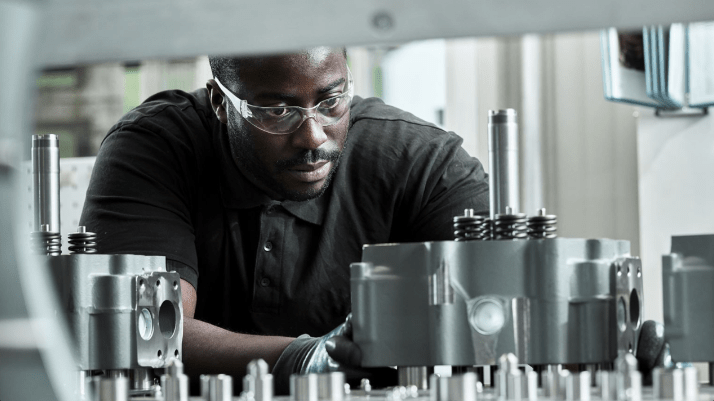

Safety is the foremost priority in the dynamic and intricate world of aviation. The complex machinery, complicated systems, and high-stakes aviation environment demand meticulous attention to detail and rigorous maintenance practices. One of the cornerstones of aviation safety is the implementation of comprehensive inspection plans. These plans play a pivotal role in ensuring the continued…

-

A Special Process is when subsequent monitoring or measurement cannot verify the output. Special Processes are critical in achieving aviation standards, and including techniques and procedures beyond conventional manufacturing methods is common practice in the industry. This article explores the definition of Special Processes and substantiates their testing and inspection in manufacturing, repair, and overhaul.…

-

Project metrics play a pivotal role in the success and efficiency of any design project. Timelines, budgets, and client satisfaction are vital aspects that demand meticulous attention throughout the project’s lifecycle. In this article, we will delve into the significance of these metrics, explore how they contribute to project success, identify potential areas for improvement…

-

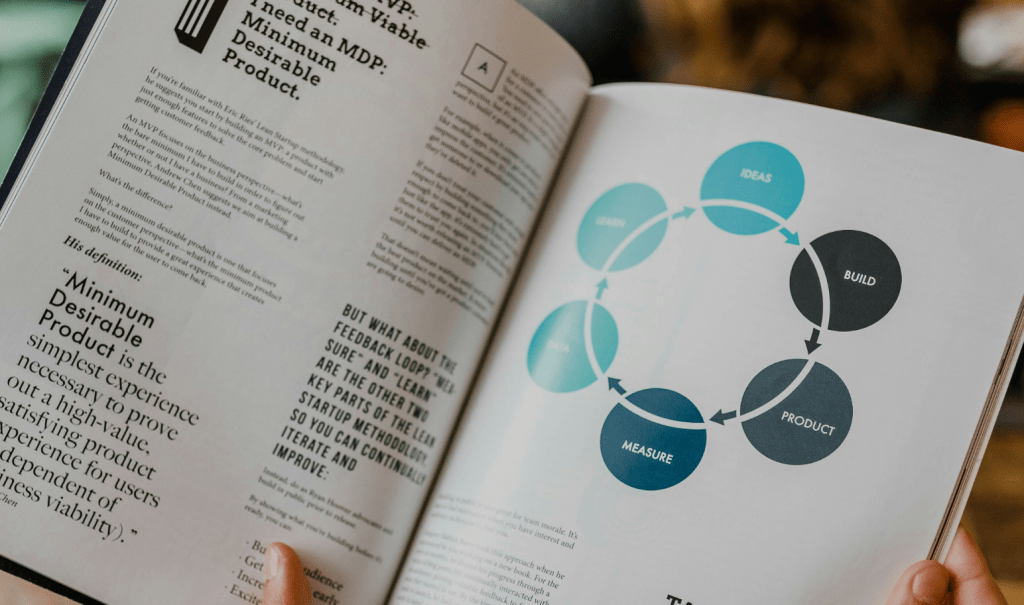

Utilizing Lean principles and methodologies can aid businesses in achieving process optimization, waste reduction, and increased efficiency. With the help of Lean tools, organizations can streamline their operations, enhance productivity, and establish a culture of ongoing improvement. Take a closer look at some of the most commonly used Lean tools that have proven to be…

-

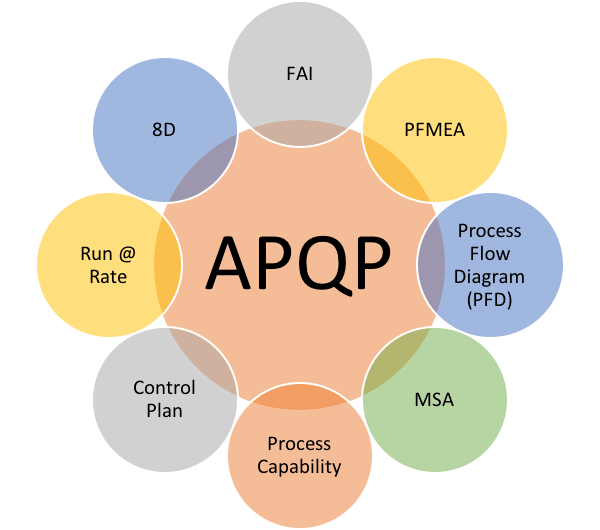

Advanced Product Quality Planning (APQP) is a systematic approach to product development and manufacturing that helps ensure product quality. It is a critical process in the aviation industry, where safety is the uppermost.

-

A Process Failure Mode and Effect Analysis (PFMEA) is a systematic approach to identifying and assessing potential failures in a process. It is used to prevent losses from occurring and to minimize their impact when they do occur.

-

Effective communication can be difficult due to the various factors involved in the process. Technical communication is even more critical because the absence of crucial details can put the entire product or batch at risk. Creating self-explanatory work instructions can offer reassurance to designers and enhance the security of technicians.

-

Value Stream Mapping (VSM) is a lean manufacturing technique that helps businesses visualize, analyze, and improve their processes. It is an essential tool in the aviation manufacturing industry where optimizing operations, reducing costs, and improving safety is paramount.