engineering

-

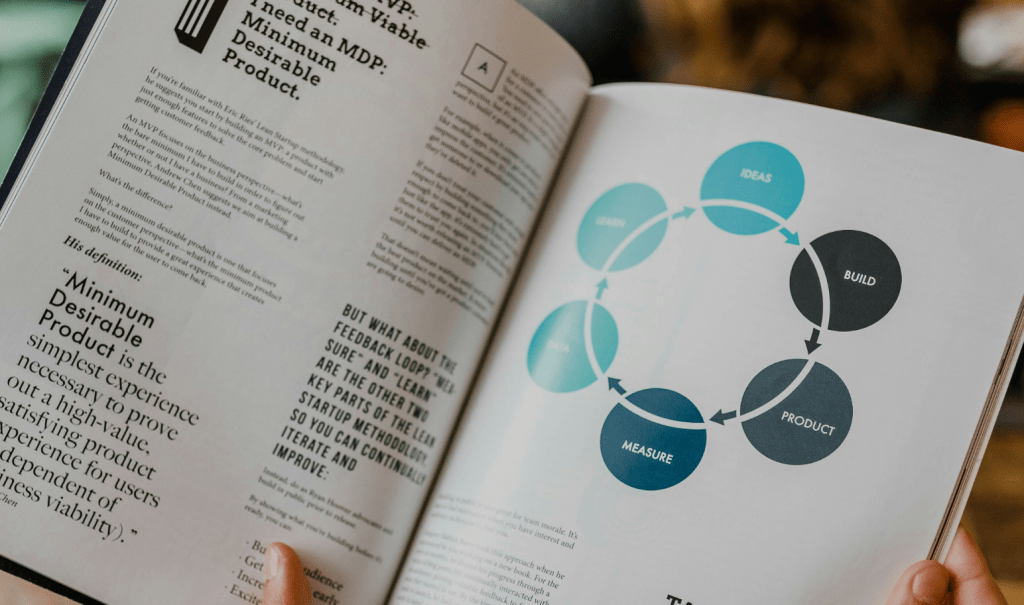

Project metrics play a pivotal role in the success and efficiency of any design project. Timelines, budgets, and client satisfaction are vital aspects that demand meticulous attention throughout the project’s lifecycle. In this article, we will delve into the significance of these metrics, explore how they contribute to project success, identify potential areas for improvement…

-

In today’s competitive business landscape, manufacturing companies are constantly seeking ways to optimize their processes. If you’re looking to create a framework for data analysis, continuous improvement, employee involvement, and technology integration, then keep reading!

-

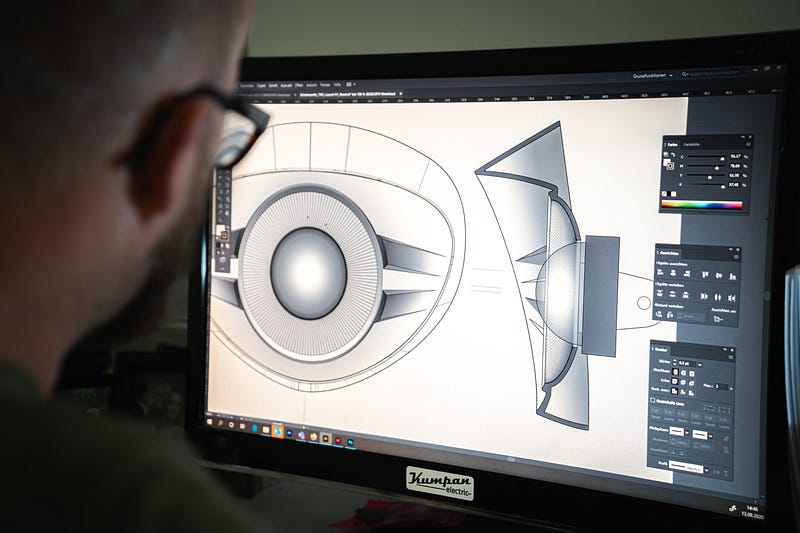

The modern world has been designed using Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software. The combination of CAD and CAM software has provided the power of computers to design skills launching more efficient manufacturing processes. These have enabled users to create detailed and accurate 2D and 3D models, allowing designers to visualize their ideas…

-

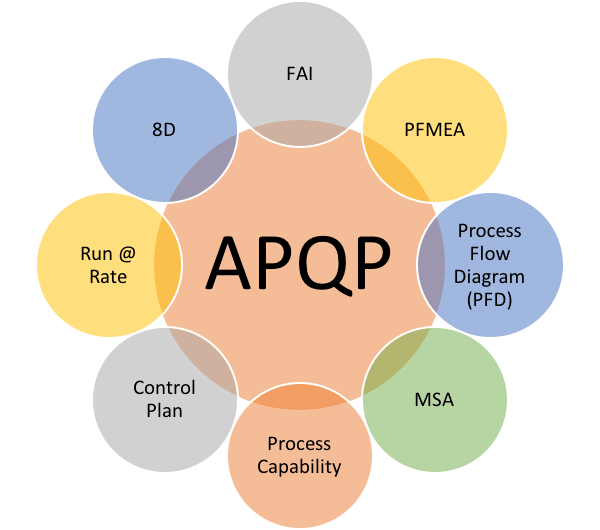

Advanced Product Quality Planning (APQP) is a systematic approach to product development and manufacturing that helps ensure product quality. It is a critical process in the aviation industry, where safety is the uppermost.

-

Humans have used paint, from cave paintings to rocket drawings, to communicate stories, events, and beliefs. Engineering drawings are the pinnacle of a breed that evolved from our dedication to building things.

-

A Process Failure Mode and Effect Analysis (PFMEA) is a systematic approach to identifying and assessing potential failures in a process. It is used to prevent losses from occurring and to minimize their impact when they do occur.

-

Effective communication can be difficult due to the various factors involved in the process. Technical communication is even more critical because the absence of crucial details can put the entire product or batch at risk. Creating self-explanatory work instructions can offer reassurance to designers and enhance the security of technicians.

-

Value Stream Mapping (VSM) is a lean manufacturing technique that helps businesses visualize, analyze, and improve their processes. It is an essential tool in the aviation manufacturing industry where optimizing operations, reducing costs, and improving safety is paramount.

-

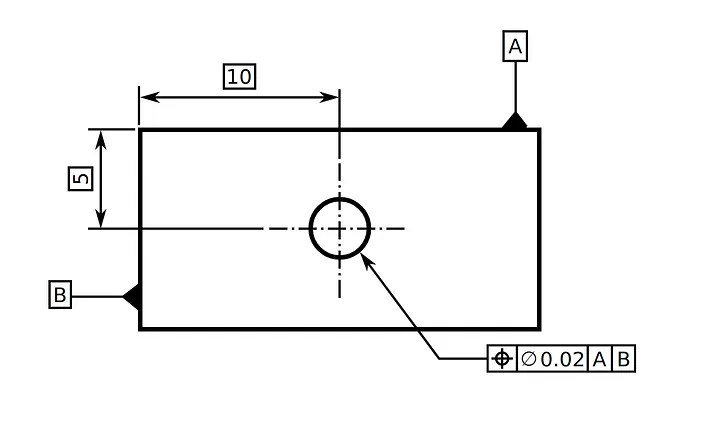

GD&T is based on a set of rules and symbols that are used to define the geometry and allowable variation of a part or assembly. The system is based on three main principles: form, orientation, and location. These principles define the shape, size, position, and orientation of features on a part or assembly.