How precisely do you think those machines in the picture have to perform? I know it is a tricky question. However, common sense will tell us: A lot!

Airplanes are quintessential pieces of engineering, second only to spaceships. This is because the extreme conditions the machine will deal with establish its design criteria.

Engineers start considering different premises like safety, cost, environmental impact, regulation compliance, amount others. Some conditions, like load, weight, speed, altitude, and temperature, must also be established. These parameters set the project premises and give a go voice to a multidisciplinary team to start working in aerodynamics, propulsion, structures, materials, and avionics.

Putting a multimillion-dollar machine in the sky requires detailed and highly specialized design, development, and manufacture. All three steps include several sub-steps, a lot of highly qualified personnel, and a constant interaction between engineering and quality to ensure industry standards.

Of the three stages mentioned, it is during manufacturing that all the initial investigations and considerations are landed (pun intended).

Aviation manufacturing is a process that involves engineering, quality, and production personnel in a symbiosis that gives high-quality products as a result. We are talking about virtually zero defects. A defective unit installed in an aircraft can take the machine down, causing a catastrophe.

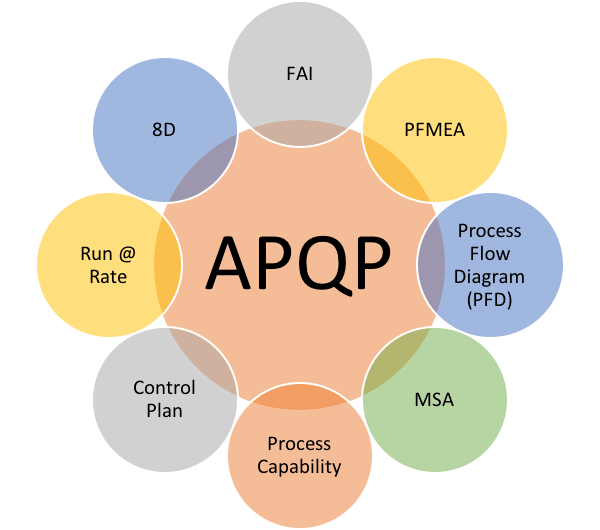

Advanced Product Quality Planning (APQP) is a systematic approach to product development and manufacturing that helps ensure product quality. It is a critical process in the aviation industry, where safety is the uppermost.

The APQP process delivers drawings, PFMEAs, work instructions, bubble drawings, inspection plans, FAIRs, BOMs, special processes, and consumables determination, among others.

APQP is developed in a five-phase process that begins with customer requirements and ends with production release. The phases are:

- Planning: The scope of the APQP is defined as to what products and processes will be covered. The customer’s requirements are gathered and analyzed. The product and process requirements are defined, and technical specs are reviewed,

- Product design and development: Key personnel involved is identified. The product is designed, and the manufacturing process is developed. A prototype is created so the considerations and lessons learned during this process can become established processes in subsequent steps,

- Process design and development: A plan outlining the steps that will be taken to implement the APQP is defined. The manufacturing process is optimized, and the necessary inspections are implemented. This ensures the smoothness and continuous relationship between the required output and all the intermediate processes,

- Product and process validation: This step will involve gathering and analyzing data, developing plans, and implementing controls. Product and process are tested to ensure they meet the client’s requirements and comply with safety and environmental regulations,

- Production release: The APQP is constantly monitored and improved to ensure that it is effective and delivers fully functional products that get manufactured and set to the customer.

APQP helps to ensure the quality of products by identifying potential problems early in the development process. It also helps to ensure that the manufacturing process can produce products that meet the requirements. This can help to reduce the number of defects and improve the overall quality of the product.

This is a valuable tool for the aviation industry. It can help improve product quality, reduce the risk of defects, and help to improve safety while reducing costs.

Good quality can be obtained in the aviation manufacturing industry by following the steps outlined. It is a significant step to produce high-quality products that meet the customer’s needs, but only some of them. There are some additional considerations for establishing an effective APQP in the aviation industry:

- Get the right people involved. A team of qualified people with experience in the aviation industry should implement the APQP,

- Use the right tools and resources. Several tools and resources are available to help you implement APQP. Make sure to use the right ones for the project’s needs,

- Get buy-in from management. The APQP must be supported by management to be successful. Make sure to get the approval and full collaboration before you start implementing the process,

- Communicate effectively. Communication is essential for the success of any APQP. Make sure you communicate effectively with all the factors involved throughout the process,

- Be patient. APQP is a long-term process. Don’t expect to see results overnight. Be patient and persistent, and eventually, the benefits of APQP will show up.

Leave a comment