#manufacturing

-

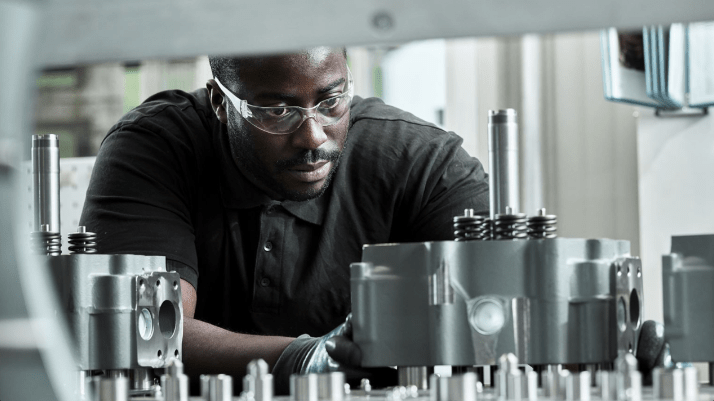

A Special Process is when subsequent monitoring or measurement cannot verify the output. Special Processes are critical in achieving aviation standards, and including techniques and procedures beyond conventional manufacturing methods is common practice in the industry. This article explores the definition of Special Processes and substantiates their testing and inspection in manufacturing, repair, and overhaul.…

-

The realm of creativity and skillful craftsmanship encompasses a diverse spectrum populated by individuals with unique talents and expertise. Three terms frequently emerge within this spectrum: artist, artisan, and craftsman. While they share commonalities in their dedication to creating objects of beauty or utility, each term carries distinct connotations and delineations. This essay aims to…

-

Precision and meticulous attention to detail is essential in the complex and highly regulated world of aviation manufacturing, fabrication, repair, and overhaul (MRO). The Bill of Materials (BOM) serves as the compass guiding this intricate journey, ensuring that each component aligns seamlessly to create aeronautical masterpieces. This article explores the generation, creation, and utilization of…

-

The aviation repair industry is highly regulated and safety-critical, making ensuring components’ quality and reliability a top priority. To achieve this, the First Article Inspection Report (FAIR) is a comprehensive documentation and verification process. FAIR is essential in guaranteeing adherence to stringent quality standards and maintaining the integrity of aviation repairs. In this essay, we…

-

The concept of product quality is more complex than it may seem. Product quality in manufacturing is not a matter of perception but a combination of tangible and intangible factors. While external appearances and pricing may influence initial impressions, true product quality lies in the product’s performance, reliability, safety, and overall customer satisfaction. This article…

-

Utilizing Lean principles and methodologies can aid businesses in achieving process optimization, waste reduction, and increased efficiency. With the help of Lean tools, organizations can streamline their operations, enhance productivity, and establish a culture of ongoing improvement. Take a closer look at some of the most commonly used Lean tools that have proven to be…

-

In today’s competitive business landscape, manufacturing companies are constantly seeking ways to optimize their processes. If you’re looking to create a framework for data analysis, continuous improvement, employee involvement, and technology integration, then keep reading!

-

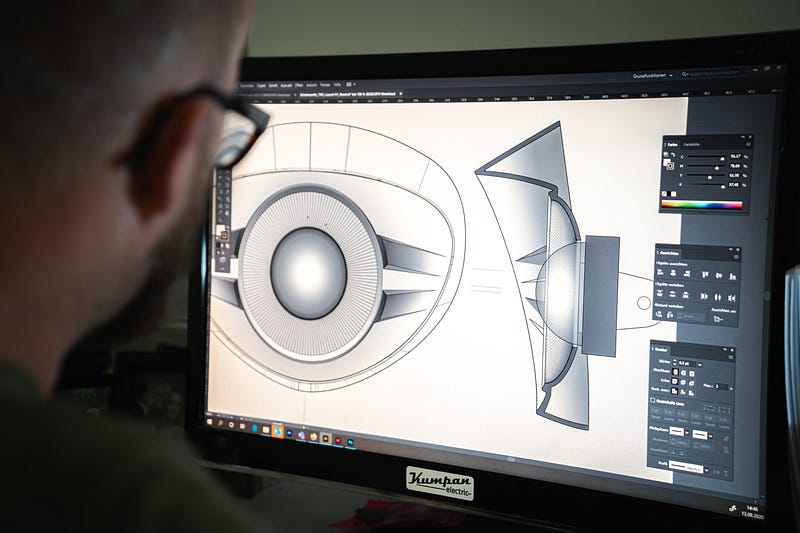

The modern world has been designed using Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software. The combination of CAD and CAM software has provided the power of computers to design skills launching more efficient manufacturing processes. These have enabled users to create detailed and accurate 2D and 3D models, allowing designers to visualize their ideas…

-

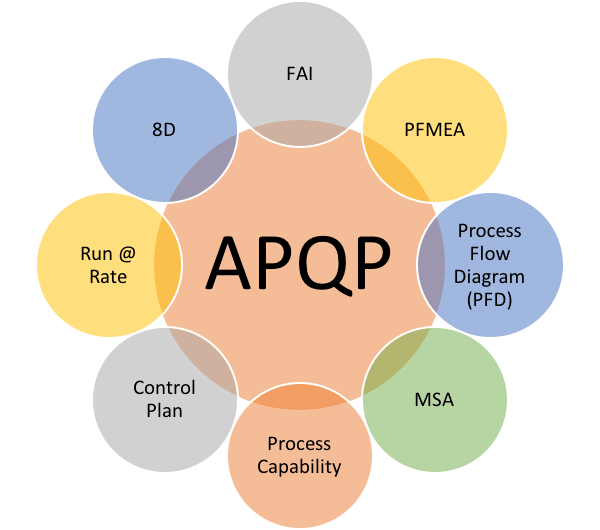

Advanced Product Quality Planning (APQP) is a systematic approach to product development and manufacturing that helps ensure product quality. It is a critical process in the aviation industry, where safety is the uppermost.

-

Humans have used paint, from cave paintings to rocket drawings, to communicate stories, events, and beliefs. Engineering drawings are the pinnacle of a breed that evolved from our dedication to building things.